ARIS '19

↑ Read Full Team Project Idea Progression on 2.009 Website ↑

Project Description

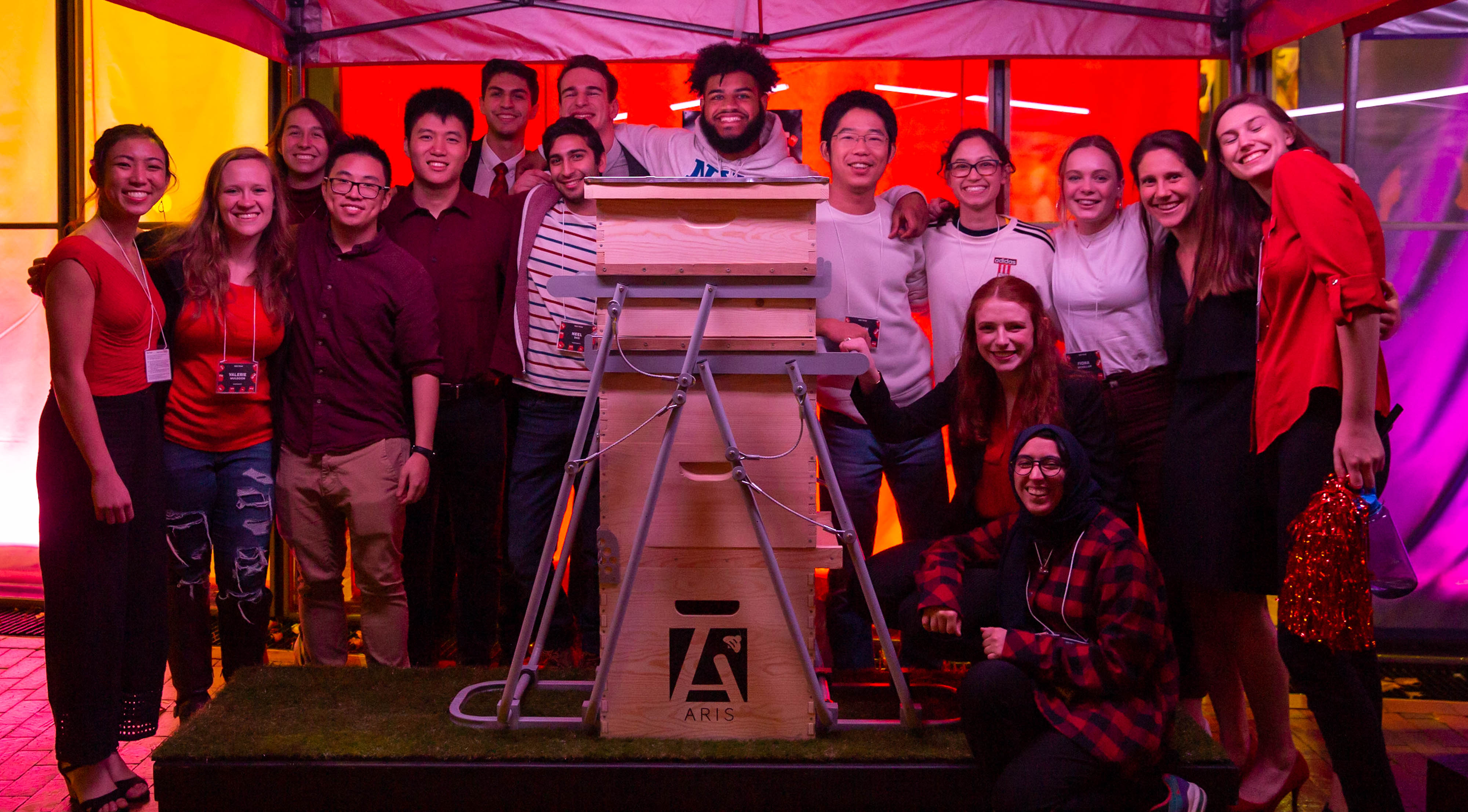

Team Members : Ben Bennington, Caroline Jordan, Devon Goetz, Fiona Mckellar, Gabe Li, Hector Castillo, Jason Ai, Kevin Zheng, Kiera Gavin, Lucy Milde, Marwa AlAlawi, Neel Das, Raymoung Tse, Sam Ihns, Serena Le, Val Hunter, Valerie Muldoon

2.009, also known as Product Engineering Processes, is a capstone senior project class for mechanical engineering students at MIT. In my team of 17 students, we worked on creating Aris, a mechanical beehive system that eliminates heavy box lifting from beekeeping. In traditional beekeping that uses the langstroth hive, boxes are placed in a vertical orientation that align with bee natural activity and comfort. A hive would typically have 4 boxes on average, with the bottom two (brood boxes) housing the bees, and the two upper boxes carrying the honey. The problem arises in routine checks that beekeepers perform that in order to check the two bottom brood boxes (which weight significantly less) but are in the bottom, and would require the lifting of the heavy upper two boxes which carry honey. This is where Aris comes in. It's a mechanical system that utilizes the concept of a four-bar linkage, and allows the boxes in the hive system to separate for easier hive access.

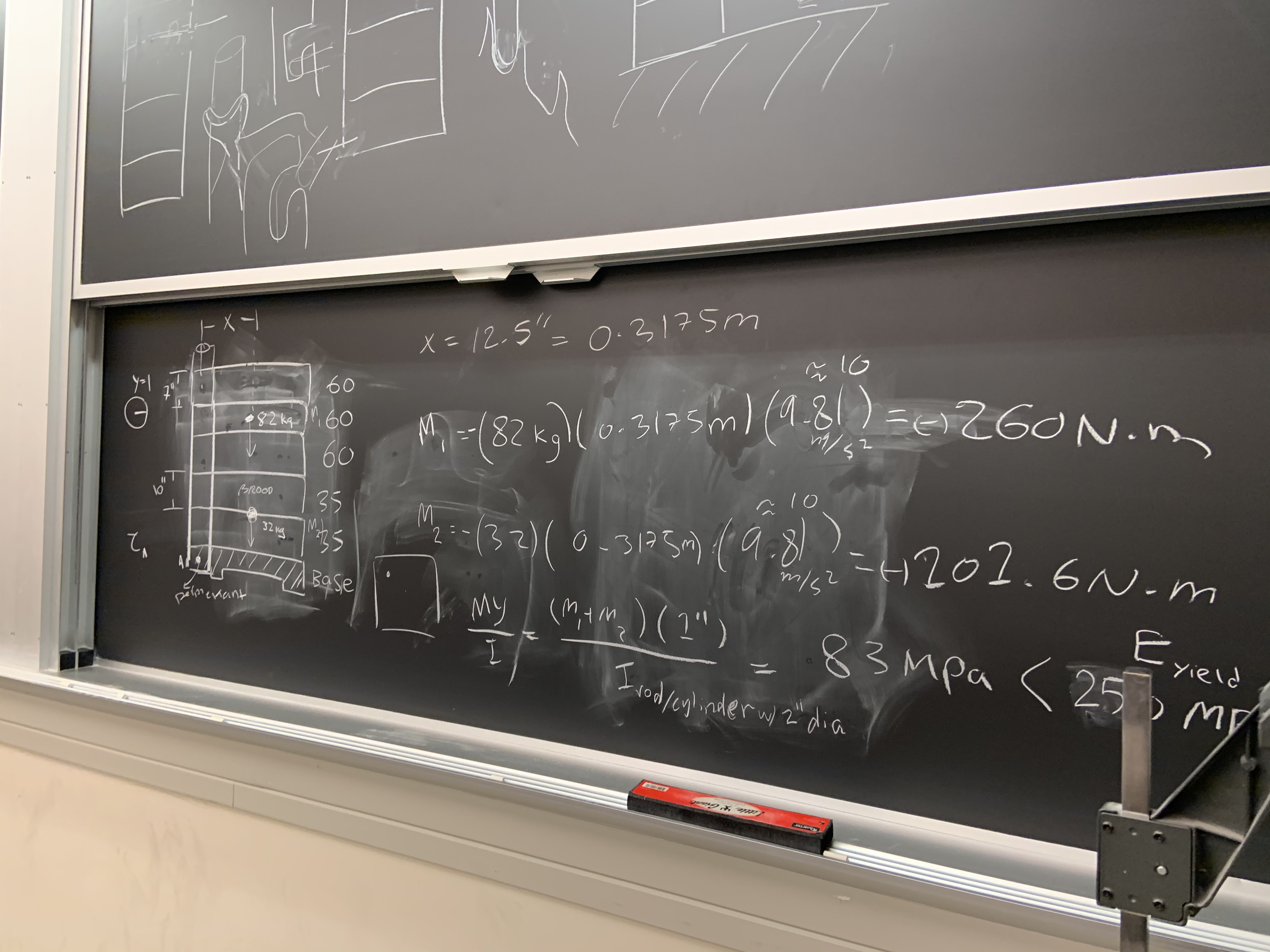

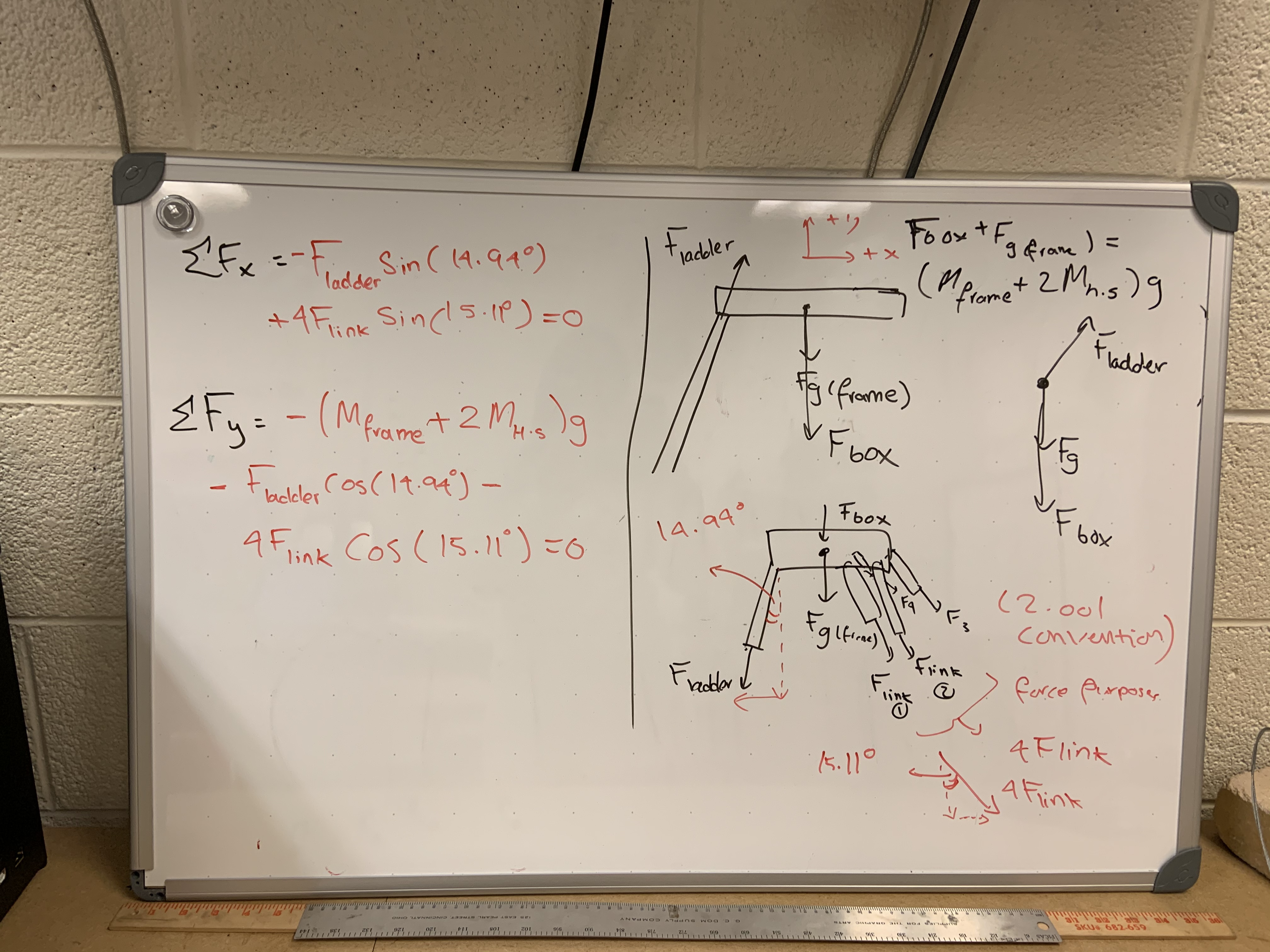

After coming up with different project concepts and researching them in terms of feasibility and market saturation, our team settled on creating Aris for our capstone project. I mostly worked on the mechanics and materials part of the project, where I performed several tests and calculations on failure modes, maximum loads, material selection, and determining dimensions of manufacturable parts aside from actual fabrication of the box holders. In addition, I designed the brand identity of Aris from logo to several graphics in the course, including the 3D animation shown in our final presentation ( I used Unity for the animation).

Project Keywords

- Product Design

- Mechanics & Material selection

- Failure Analysis (Matlab)

- Fabrication

- CAD (Solidworks)

- Prototyping

- Animation (Unity)

- Public Speaking